Proven Expertise Across Multiple Sectors

Building Excellence from Design to Delivery

Our experience spans the complete project lifecycle—from feasibility studies and engineering design to construction, installation, and commissioning. This collective capability allows us to offer tailored, end-to-end solutions that meet the demanding requirements of each industry.

We operate with a firm commitment to QHSE excellence, embedding the highest standards of Quality, Health & Safety, and Environmental sustainability into every project we undertake. Our team’s approach is proactive, compliance-driven, and focused on continuous improvement—ensuring not just successful delivery, but safe and responsible execution.

The projects featured below represent the depth of our team’s achievements and our shared commitment to operational excellence.

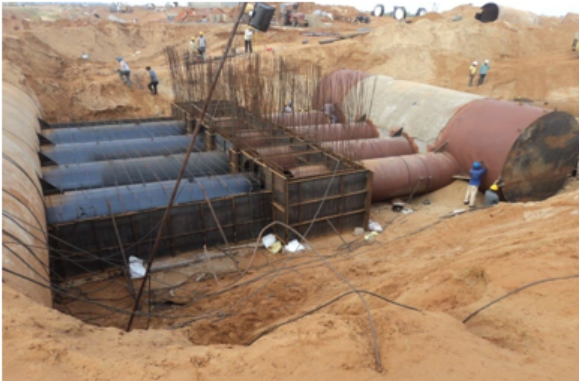

Marine Projects

Click to explore our key contributions to marine infrastructure:

- Construction of seawater intake wells

- Design & fabrication of oil barges

- Custom-built cutter suction dredgers

- Salvage operations for marine vessels

- Design & construction of tugs and ships

All projects are executed with precision, reliability, and strict adherence to QHSE standards.

Read More

Specialized Defense Projects

Click to explore our key contributions to the defense sector:

- Design & manufacture of floating canopies

- Damage control simulators for naval training

- Dock blocks for dry docks and vessel support

- LP air systems for onboard applications

- SS 316 Ti piping for submarines

- Retrofit of naval tugs

- Design & construction of caisson gates and barges

All projects are delivered with a strong focus on functionality, durability, and strict adherence to QHSE and military standards.

Read More

Oil & Gas Projects

Our team has delivered a range of critical EPCIC solutions for the Oil & Gas sector. Key works include:

- Design and installation of 24” subsea crude oil pipelines

- Installation of remotely operated vehicles (ROVs)

- Integration of moon pool sliding door systems on MPSV

- Single Point Mooring (SPM) system works, including fabrication of PLEM, pile drivers, and installation aids

These projects reflect our TEAM capability in executing complex offshore and onshore energy infrastructure with a strong commitment to QHSE compliance, technical precision, and operational integrity.

Read More

Heavy Engineering Projects

Click to explore key heavy engineering works executed:

- Design, fabrication, and installation of rotary furnaces

- Cement handling conveyor systems – including bucket assemblies, wheels, and chutes

- Use of special-grade steels: Manganese Steel, Hardox, Stainless Steel, Carbon Steel

- 40-foot trailer with 40-tonne SS316 tank for DM water transport

These projects demonstrate our capability in delivering robust, custom-engineered solutions for demanding industrial environments with full adherence to QHSE standards.

Read MoreEngineering Beyond Boundaries

At MIEPL, sustainable innovation isn’t a promise—it’s our foundation.